iFortress: Independent Testing on a full assembly including DOD Testing

Licensed engineers, the New Jersey Institute of Technology, Intertek ETL, AKRON, ASTM, The United States Marine Corps, and The United States Army Developmental Test Command at Aberdeen Proving Grounds participated with this testing. 100% of the DOD testing for the Pentagon was conducted on an exterior assembly that was subjected to extreme conditions exceeding normal environmental or human elements. These extreme conditions included loading, racking, hurricane force sustained winds, explosions, force entry, and a 4 megawatt crib fire. Upon the completion of the testing, the unit remained standing with no negligible structural defects other than the panels subjected to the fire assault. In the Lab testing, a unit baked at 1,800 degrees for 90 minutes and water hosed immediately after it was removed from the oven. After all the testing, the structural integrity of the MCF Series iFortress™ was intact.

Fire testing of a complete unit by the American Society of Testing Materials (ASTM) iFortress achieved an E-119 Class 125 enclosures rating for 90 minutes at 1,800 degrees.

The unit also has a Department of State RF, Sound Transmission Classification (STC) Group I to IV Sensitive Compartmental Information Facility (SCIF) classification. The iFortress meets the ICD 705/ ICS 705.1 STC and structural standards required of a SCIF.

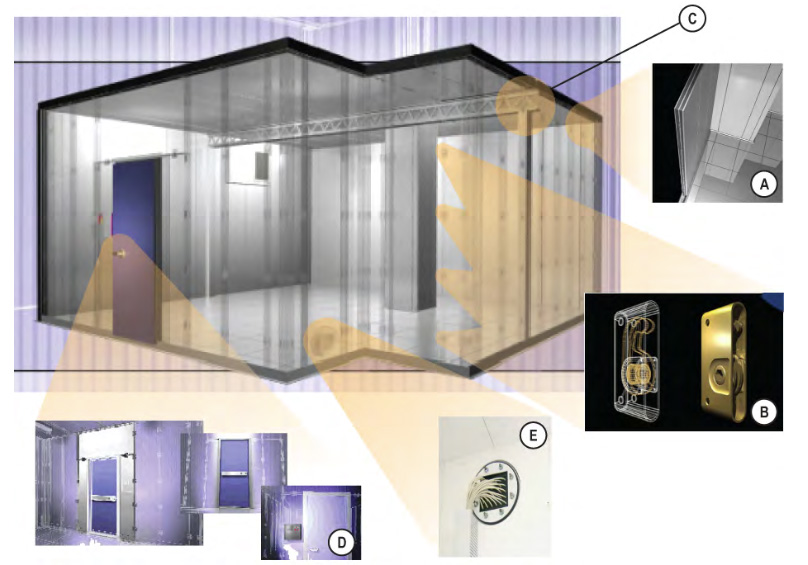

iFortress technologies provide for Structural, Hydro-Dynamic, Fire/Thermal, and Environmental security via a modular, deployable system:

- iGuard™ Armor Panel assembly (A) – using recycled steel for the walls and ceiling provides modularity and ease of expansion in the field (no disruption to ongoing operations)

- Gasket material is inert, non-conductive/combustible, intumescent, air/water tight seal and rated -3500F to +1,8000F

- iMount™ Interlocking Technology (B) – ensures all panels are properly sealed via visual indicator

- Joist System (C) – employs open web design which facilitates cabling and ducting installation

- iPassage™ door systems (D) – feature double steel wall construction with performance specific core (rated or non-rated), continuous security piano-hinge design, crash bar, and interface-able with identity management systems

- Rapid Deployment – using standard tools, assembly time is measured in hours or days (2,500 sqft facility, completed in 6 days/170 man hours)

- iPortal™ Purpose specific systems (E) – to manage penetrations (electric, heat/AC, cabling (depicted), etc.) while maintaining rated performance

- Air tight, water tight, fire/thermal protection

- Standardizing Site Variables – location variables are eliminated from the deployment process

- Interior and exterior (all weather) applications are suitable for iFortress systems

- Repeatable Processes – ensure consistent quality of all iFortress systems

- LEED compliant – eco-friendly (scalable, reusable, recyclable), which reduces operating power consumption by 25% – 35%